What is underfloor heat and why is it required in a freezer?

When Clarion builds a freezer, it’s going to require underfloor heat. No exceptions. We are protecting the client's investment. So you may ask, what is underfloor heat and why is it required in a freezer?

It’s a method of warming the soil under a newly constructed freezer floor paired with floor insulation and a vapor barrier. The goal is to keep the water table from freezing in the soil.

Though it comes in many forms, we have two simple methods:

- Under 3,000 sq ft: Self-regulating heat tape laid every 4 feet on center in PVC conduit. It’s safe, simple, and maintenance free.

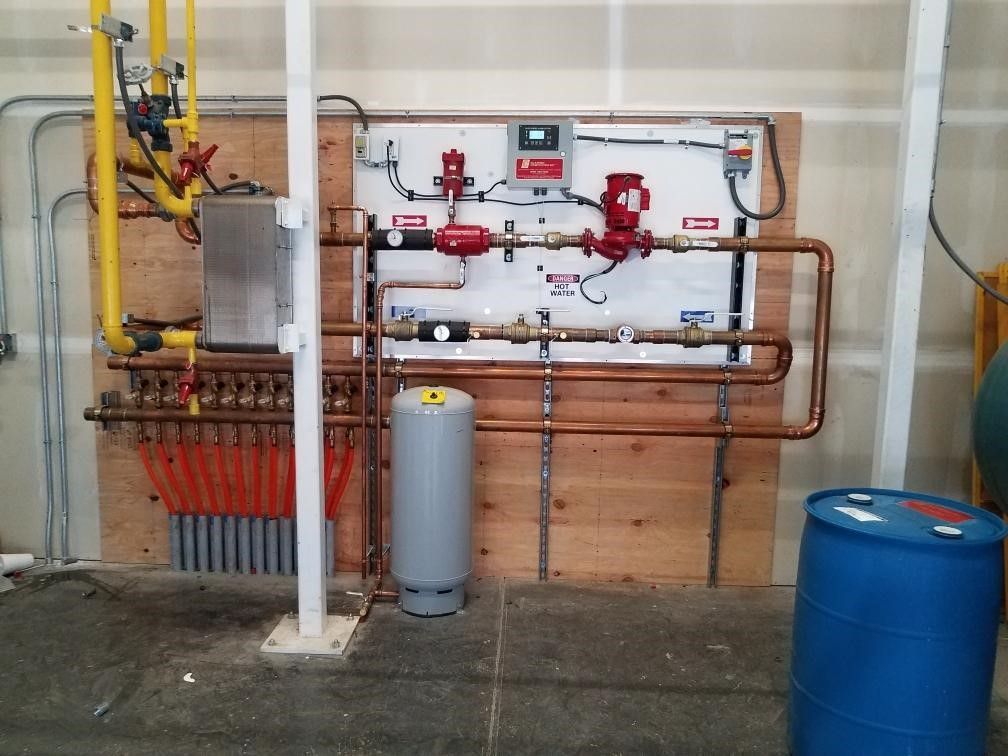

- Over 3,000 sq ft: A closed loop glycol underfloor heat system. Ridged hoses laid every 4 feet OC in long loops. All hoses are tied back to manifolds to result in equal flow for every loop. This consists of an electric water heater, flow wheels, and temperature sensors. It's a very simple, low maintenance system.

If you are looking to save electrical, you can capture the wasted heat off the refrigeration equipment, run it to the heat exchanger and warm the glycol fluid.

If you do not install this system, you can potentially freeze the soil, causing expansion and heaving in the concrete slab. We have seen slabs rise up to 14” in some cases. This caused major slab and structure failure.

Call Clarion for your next freezer project. We have been laying underfloor heat since 1988. This is what we do.

Let’s work together.